Amount of funding awarded

$346.84

Budget Report

View budget report.

How the program has supported you

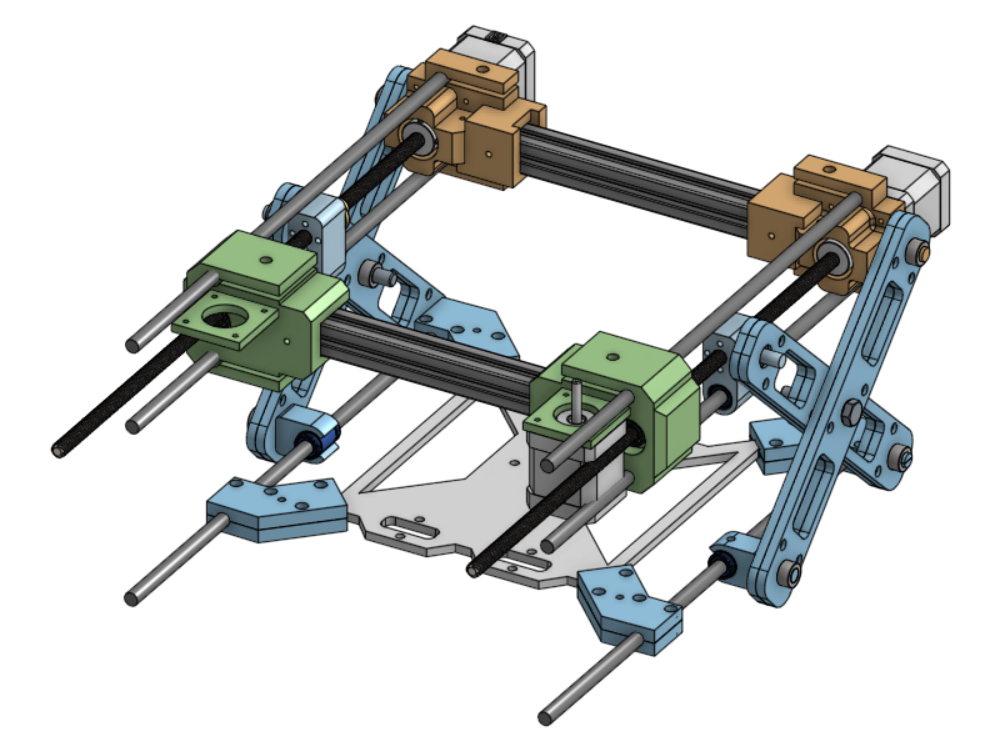

The PAF funding has facilitated our project by bridging the gap between theoretical design and a full-scale physical prototype. The PAF program has provided us with the integral funding needed to purchase components like stepper motors, bearings and PLA filament amongst many others. Over the past year, we have made progress by leaps and bounds and almost completed our mechanical prototype. We’re now embarking on refining the mechanical design along with developing the software and electronics stack. The PAF funding has contributed towards our electric purchases greatly which has facilitated our innovation.

Our team gained more experience in complex assemblies and designing specific parts to be 3d-printed. Through this process and actually building the prototype, our team has also become more skilled in collaborating online and in person to develop and reiterate our designs, and gained a deeper understanding of the mechanics of a 3D printer from the ground up.

Outcomes

The briefcase printer is a wholistic mechatronic platform. It has provided our team members with the opportunity to innovate on the mechanical, electrical and software fronts. We have used a non-conventional gantry (CoreXY) and are flashing our own firmware on the printers. Once the platform is ready, it can be used for software developments as well (such as IoT printers running a custom operating systems). The aforementioned points elucidate the impact it has had on our students and its potential. These skills are vital to industry and we hope everyone will carry them through their careers.

Currently, our team has built the mechanical components of the CoreXY and folding bed mechanism of the printer. This includes the extruder assembly, the motors and belt setup required to control its movement, and the X shaped frame that folds the bed up to the CoreXY in not unlike a scissoring movement.